Anti Seize Compounds

Anti seize compounds are a huge thing to have especially in highly corrosive areas. Highly corrosive areas are where you will need to use anti seize compounds to make sure that there is no corrosion or to make sure corrosion is not as fast.

Anti seize compounds can also improve gasket performance as well. Not only help with performance but help during the removal process of a gasket also. Anti seize lubricants can help to prevent thread galling during installations which can cause problems and even more money if this problem happens.

It is important to know what anti-seize is. Straight out of the tube or bottle, anti-seize is made up of a high-quality grease base and lubricating solids (copper, graphite, aluminum, calcium oxide etc.), which are suspended in the grease. Unfortunately, getting the right anti-seize compound in the right quantity onto each fastener has always been a messy operation and one in which over application wastes product and under application can reduce its effectiveness.

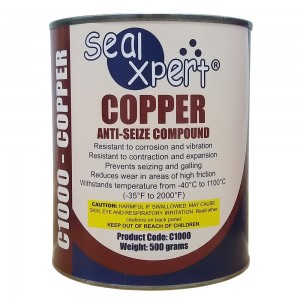

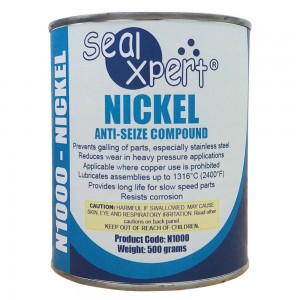

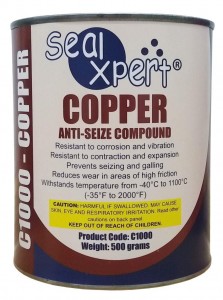

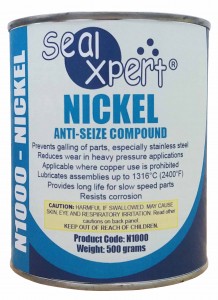

Most anti-seize compounds originally contained copper and graphite or copper, aluminum, and graphite, which tended to work for most applications, in standard settings. These anti-seize compounds were well suited to high temperature applications since aluminum can withstand temperatures 1000°F, copper to 1800°F and graphite to over 2000°F. However, since copper and aluminum are reactive metals, they were ill suited for some applications exposed to substances like acetylene and ammonia. For extreme high temperature applications, or those where a non-reactive compound was needed, special anti-seize compounds such as nickel or molybdenum disulfide (Moly) were developed.

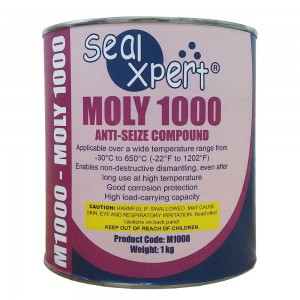

Most of out anti seize compounds product can be use for general purpose, and SealXpert product for anti seize compounds is also has wide range variety of feature so you can have more product option that can suit your needs.

SealXpert wide range variety product can be found from low strength to powerful high strenght mixed with low viscosity to high viscosity, from easy removal to perfect for metal bonding, Its all good in lubricity and any features combined for perfect anti seize compound products. You can always go to this link -> SealXpert Maintenance to find a perfect product for your needs.

SealXpert is an ISO certified company offering a range of proven products for pipeline maintenance. SealXpert products eliminate or minimize the costs of plant and equipment downtime.

Other than anti seize compounds, we have a wide range of products that will save your time and money to prevent corrosion such as: SealXpert Anaerobic Threadlocker, SealXpert Anaerobic Thread Sealant, SealXpert Anaerobic Flange Sealant, SealXpert Anaerobic Retaining Compound, SealXpert Cyanoacrylate Adhesive, SealXpert Molybdenum Lubricant Products, SealXpert Aerosol Products.